a better way to make core-shell hydrogel particles

dual gelations synthesize core-shell particles in a single step

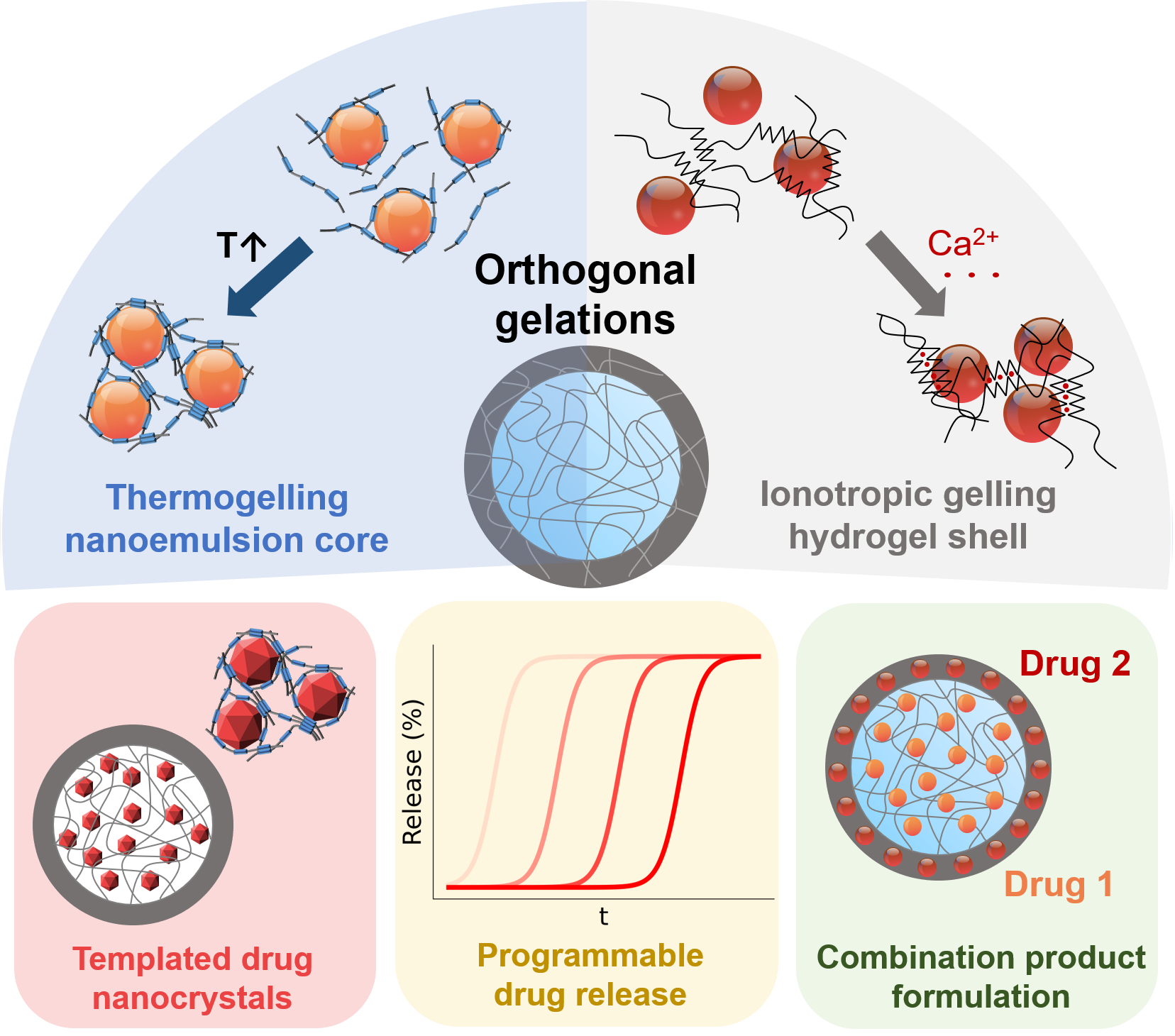

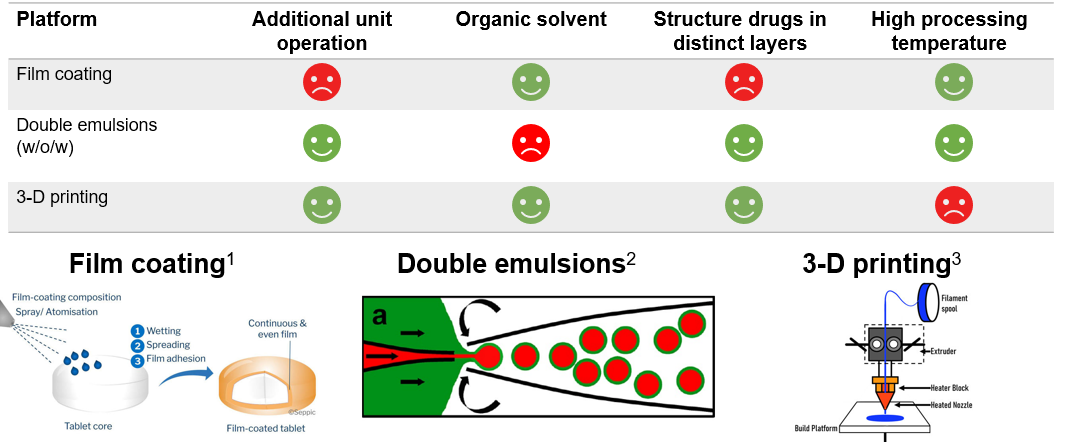

This project, the first in my PhD, focused on figuring out a clever way to engineer core-shell hydrogel drug carrier particles. Core-shell particles are extremely useful in oral drug delivery. They can unlock sustained and delayed release profiles, which is important for instestinal and colonic targeting applications. They can also formulate fixed dosage combination (FDC) products, structuring different active ingredients in the core and the shell. Despite these useful applications, conventional methods for engineering core-shell carriers for pharmaceutical applications are limited, relying on organic solvents, high processing temperatures, and are often unable to structure drugs in the shell (see below).

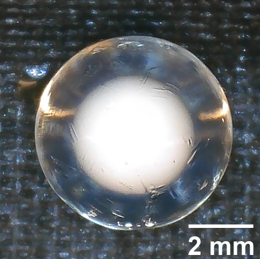

With this project, we invented a clever way to circumvent these challenges by making two different types of hydrogels in a single core-shell structure. We rely on methylcellulose and alginate-based hydrogels to do this. Methylcellulose gels thermally (gels when heated, opposite of gelatin), while alginate gels from salt crosslinking. By dripping a salty methylcellulose solution (loaded with whatever cargo you want to encapsulate) into a syringe and dripping droplets into a heated alginate bath, we can trigger the methylcellulose thermal gelation of a droplet into a ‘core,’ encapsulating the cargo. Simultaneously salt diffuses out of the core into the bath and crosslinks alginate, generating a gel ‘shell’ layer. In one stop, we have generated an all-aqeuous core-shell particle. The process is simple, avoids the use of an organic solvent, is gentle (methylcellulose can gel in temperatures as low as 33 C), and provides is an opportuntity to encapsulate different cargo in each layer, with no overlap. Plus, the particles end up looking beautiful!